Major features and innovations of MIB 85-C INJECTION STRETCH BLOW MOLDING MACHINE are:

Video:

Machine Specification

| Model No. | UNIT | MIB 85-C |

| Screw Diameter | mm | 85 |

| Injection Capacity | cm3 | 1440 |

| Screw Heating Capacity | kw | 24.7 |

| Injection Clamping Force | ton | 61 |

| Injection Mold Daylight | mm | 580 |

| Blowing Mold Clamping Force | ton | 41 |

| Blowing Mold Opening Stroke | mm | 400-800 |

| Maxinum Blowing Air Pressure | kg/cm2 | 20 |

| Blowing Air Pressure | kg/cm2 | 14 |

| Operation Air Pressure | bar | 8 |

| Hydraulic Motor | hp | 50HP+100HP |

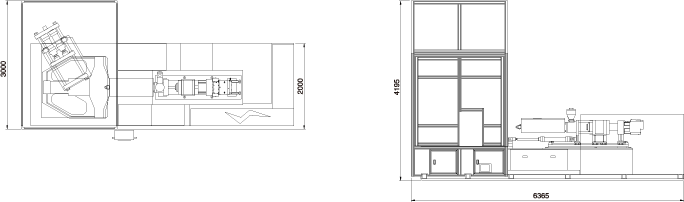

| Machine Size(L x W x H) | mm | 9,500 x 4,000 x 5,500 |

| Machine Weight | ton | 15.0 |

*All specifications and designs are subject to change without notice.

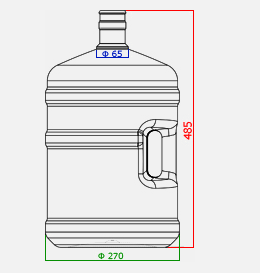

- Approximate Capacity (Gallon) 5 G

- Neck Diameter 65 mm

- Body Diameter 270 mm

- Height Diameter 485 mm

This model of one-stage, three station in ection stretch blow molding machine is made by KAI MEI plastic machinery co. Itd. It has the possibility to economically produce high quality contain

ers using various of many kinds of material in PET,PP,PC,TRITAN,PES,etc. and save energy. It

lets our customers obtain the most profits with the fast cycle time from this injection stretch blow-molding machine.

This model of one-stage, three station in ection stretch blow molding machine is made by KAI MEI plastic machinery co. Itd. It has the possibility to economically produce high quality contain

ers using various of many kinds of material in PET,PP,PC,TRITAN,PES,etc. and save energy. It

lets our customers obtain the most profits with the fast cycle time from this injection stretch blow-molding machine.

PROCESSING WITH 3 STATION ROTARY TABLE

The process of this machine is by using a rotary disk to cycle three stations. At the first station,there is a high clamping force on the inection mould of this machine to ensure obtaining a good performace quality. At the second station, we assigned a controller to adjust the temperature so that our customers could obtain the best quality bottles. At the third station, it is in process of the stretching and high pressure blowing shape. At the last station,high quality bottles can be easily taken out.

3 STATIONS PRODUCTION PROCESS

STATION 1: PREFORM INJECTION MOULDING STATION

The clamping mould of this machine is quickly clamped by using two small hydraulic cylinders and is finally clamped by a large diameter cylinder with a high clamping force that can reach 30 tons. The material is injected into the mold of the hot runner system and cooled down rapidly to 95-100 C. and that it is cleanly shaped.STATION 2: STRETCH BLOW STATION

To stretch the perform by using a thin long stick and holding the button on to blow at high pressure to shape.STATION 3: PRODUCT EJECTING STATTION

The products here are at the final station. Using pneumatics to open the neck mould,the products can simply be taken out.SPECIFICATION OF MACHINE

| Model No. | UNIT | MIB 75 | MIB 65 | MIB 55 | MIB 45 |

| Screw Dia. | mm | 75 | 65 | 55 | 45 |

| lnjection Capacity | cm3 / shot | 884 | 565 | 333 | 175 |

| Screw Heating Capacity | kw | 12.5 | 10 | 7 | 4.2 |

| lnjection Clamping Force | ton | 102 | 102 | 61 | 33 |

| Blowing Mold Clamping Force | ton | 55 | 43 | 34 | 18 |

| Maximum Blowing Air Pressure | bar | 30 | 30 | 30 | 30 |

| Air Pressure System | bar | 8 | 8 | 8 | 8 |

| Hydraulic Pack Pump Motor | hp | 75 | 60 | 50 | 40 |

| Operating Hydraulic Pressure (max) | kg / cm2 | 140 | 140 | 140 | 140 |

| Total power consumption | kw | 82.5 | 64.5 | 50.5 | 35 |

| Machine Size | LxWxH(M) | 6.5*3.4*5 | 5.8*3*4.7 | 5.4*2.4*4.2 | 4.5*2.0*3.4 |

| Machine weight | ton | 20 | 16 | 11 | 7 |

*For more detailed information, please contact manufacturer.

*All specifications and designs are subject to change without notice.

*All specifications and designs are subject to change without notice.

PRODUCT DIMENSIONS

| Model No. | Number of Cavitives | 1 | 2 | 4 | 6 | 8 |

| MIB 45 | Approximate Capacity | 2 | 1.5 | 0.5 | ||

| Neck Diameter | 70 | 55 | 40 | |||

| Body Diameter | 105 | 100 | 55 | |||

| Height | 300 | 300 | 250 | |||

| MIB 55 | Approximate Capacity | 5 | 2.5 | 1.5 | 0.6 | |

| Neck Diameter | 80 | 75 | 55 | 35 | ||

| Body Diameter | 170 | 130 | 90 | 66 | ||

| Height | 350 | 350 | 320 | 250 | ||

| MIB 65 | Approximate Capacity | 3 | 2 | 0.8 | 0.35 | |

| Neck Diameter | 80 | 70 | 40 | 35 | ||

| Body Diameter | 130 | 105 | 80 | 50 | ||

| Height | 350 | 335 | 270 | 250 | ||

| MIB 75 | Approximate Capacity | 5 | 2.5 | 1 | 0.5 | |

| Neck Diameter | 80 | 70 | 50 | 35 | ||

| Body Diameter | 170 | 130 | 80 | 55 | ||

| Height | 350 | 350 | 300 | 250 |

*All specifications and designs are subject to change without notice.

*For more detailed information, please contact manufacturer.

*For more detailed information, please contact manufacturer.