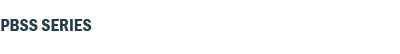

KM Model NO. PBSS-605 / 705 (S / D / T / Q)

Double station machine, full automatically, suitable for producing high-production runs of medium size bottles,

ex. Cosmetic bottles detergents,

etc. Mold-platen moves properly with high stability and high efficiency

- Three tie-bar horizontal traveling mold carriage combined with German linear motion guides for outstanding performance and high efficiency.

- This series is designed to meet high production and small size container requirements. Available to equip with auto de-flashing device and take out robot to achieve fully automatic and highly efficient production.

- 10" TFT colorful LCD screen with human-machine interface control system. It provides powerful functions, convenient and user-friendly operation.

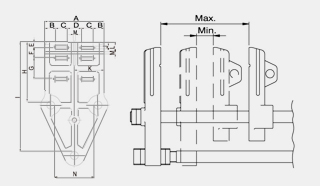

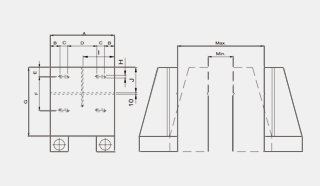

| NO. | PBSS-605 | PBSS-705 | NO. | PBSS-605 | PBSS-705 |

| Max. | 320 | 420 | G | 107 | ~ |

| Min. | 60 | 80 | H | 300 | 327.5 |

| A | 260 | 300 | I | 556 | 632.5 |

| B | 55 | 48 | J | 14 | 18 |

| C | 60 | 57 | K | 150 | 150 |

| D | 70 | 90 | L | 50 | 81.5 |

| E | 27 | 40 | M | 10 | 10 |

| F | 53 | 92 | N | 200 | 180 |

- For use with in-mold labeling machine. Open-close clamping mold is specified upon request.

| Model No. | UNIT | PBSS-605S | PBSS-605D | PBSS-605T | PBSS-605Q | PBSS-705S | PBSS-705D | PBSS-705T | PBSS-705Q |

| Product capacity | C.C. | 80-,1000 | 50-500 | 30-200 | 10-100 | 450-2,500 | 200-1,000 | 50-500 | 30-200 |

| Product diameter | mm | 30-100 | 20-80 | 15-65 | 8-30 | 45-150 | 30-100 | 20-80 | 15-65 |

| Screw diameter | mm | 65 | 65 | 65 | 65 | 75 | 75 | 75 | 75 |

| Screw L/D ratio | 24/1 | 24/1 | 24/1 | 24/1 | 24/1 | 24/1 | 24/1 | 24/1 | |

| Inverter motor | HP | 20 | 20 | 20 | 20 | 40 | 40 | 40 | 40 |

| Screw rotation speed | r.p.m. | 15-65 | 15-65 | 15-65 | 15-65 | 15-65 | 15-65 | 15-65 | 15-65 |

| Extruding capacity | kg/hr | 55 | 55 | 55 | 55 | 75 | 75 | 75 | 75 |

| Max. Die mouth diameter | mm | 55 | 40 | 35 | 25 | 80 | 50 | 40 | 35 |

| Mould center distance | mm | ~ | 100 | 85 | 75 | ~ | 120 | 100 | 85 |

| Clamping force | ton | 4.5 | 4.5 | 4.5 | 4.5 | 5.3 | 5.3 | 5.3 | 5.3 |

| Hydraulic drive motor | HP | 15 | 15 | 15 | 15 | 20 | 20 | 20 | 20 |

| Dry cycle | sec. | 3X2 | 3X2 | 3.2X2 | 3.2X2 | 3.3X2 | 3.3X2 | 3.6X2 | 3.6X2 |

| Air pressure | bar | 6-8 | 6-8 | 6-8 | 6-8 | 6-8 | 6-8 | 6-8 | 6-8 |

| Air consumption | L/min | 1,000 | 1,000 | 1,200 | 1,200 | 1,300 | 1,300 | 1,300 | 1,300 |

| Total power consumption | kw/h | 37.6 | 38.1 | 42.3 | 42.6 | 58.5 | 62.0 | 63.0 | 69.0 |

| Machine net weight | kg | 5,000 | 5,000 | 6,000 | 6,000 | 6,000 | 6,000 | 7,500 | 7,500 |

| Gross weight | kg | 6,800 | 6,800 | 7,800 | 7,800 | 8,000 | 8,000 | 9,000 | 9,000 |

| Machine dimensions | m | 4x3.3x2.6 | 4x3.3x2.6 | 4.1x3.5x2.6 | 4.1x3.5x2.6 | 4X3.3X2.4 | 4X3.3X2.4 | 4.1X3.7X2.4 | 4.1X3.7X2.4 |

KM Model NO. PBSS-905 / 1005 (S / D / T / Q)

- Powerful, crank-type mold clamping system combined with German linear motion guides for outstanding performance and high efficiency.

This series is designed to meet high production requirements. Available to equip with auto deflashing device and take-out robot to achieve fully automatic, highly efficient production. - 10" TFT colorful LCD screen with human-machine interface control system. It provides powerful functions, maximum operational convenience and user-friendly operation.

| NO. | Max. | Min. | A | B | C | D | E | F | G | H | I | J |

| PBSS-905 | 500 | 160 | 380 | 50 | 50 | 180 | 60 | 196 | 415 | 18 | 185 | 150 |

| PBSS-1005 | 640 | 240 | 420 | 65 | 50 | 190 | 60 | 220 | 449 | 18 | 205 | 165 |

- For use with in-mold labeling machine. Open-close clamping mold is specified upon request.

| Model No. | UNIT | PBSS-905S | PBSS-905D | PBSS-905T | PBSS-905Q | PBSS-1005S | PBSS-1005D | PBSS-1005T | PBSS-1005Q |

| Max. product capacity | C.C. | 1,000-5,000 | 600-2,700 | 200-,1,000 | 50-500 | 2,500-10,000 | 1,500-5,000 | 600-2,700 | 200-1,000 |

| Min./Max. dia. of product | mm | 75-200 | 60-140 | 30-100 | 20-80 | 100-250 | 80-180 | 60-140 | 30-100 |

| Screw diameter | mm | 90 | 90 | 90 | 90 | 100 | 100 | 100 | 100 |

| Screw L/D ratio | 24/1 | 24/1 | 24/1 | 24/1 | 26/1 | 26/1 | 26/1 | 26/1 | |

| Inverter motor | HP | 60 | 60 | 60 | 60 | 75 | 75 | 75 | 75 |

| Screw rotating speed | r.p.m. | 15-65 | 15-65 | 15-65 | 15-65 | 15-65 | 15-65 | 15-65 | 15-65 |

| Extruding capacity | kg/hr | 130 | 130 | 130 | 130 | 180 | 180 | 180 | 180 |

| Outer diameter of die mouth | mm | 150 | 80 | 50 | 40 | 200 | 135 | 80 | 50 |

| Mould center distance | mm | ~ | 160 | 120 | 100 | ~ | 250 | 160 | 120 |

| Clamping force | ton | 10.3 | 10.3 | 10.3 | 10.3 | 16.8 | 16.8 | 16.8 | 16.8 |

| Oil hydraulic drive motor | HP | 25 | 25 | 25 | 25 | 40 | 40 | 40 | 40 |

| Dry cycle | sec. | 4.8X2 | 4.8X2 | 5X2 | 5X2 | 5X2 | 5X2 | 5.2X2 | 5.2X2 |

| Pressure of air | kg/cm2 | 6-8 | 6-8 | 6-8 | 6-8 | 6-8 | 6-8 | 6-8 | 6-8 |

| Compressed air consumption | L/min | 2,000 | 2,000 | 2,000 | 2,000 | 2,400 | 2,400 | 2,400 | 2,400 |

| Total power consumption | kw/h | 86.6 | 88.4 | 89.4 | 91.1 | 108.1 | 113.2 | 116.6 | 119.9 |

| Machine net weight | kg | 10,000 | 10,000 | 10,000 | 10,000 | 12,000 | 12,000 | 14,000 | 14,000 |

| Gross weight | kg | 12,000 | 12,000 | 12,000 | 12,000 | 13,500 | 13,500 | 15,500 | 15,500 |

| Machine dimensions | m | 4.6x4.4x2.8 | 4.6x4.4x2.8 | 4.8x4.5x2.8 | 4.8x4.5x2.8 | 5.3x6.2x3.2 | 5.3x6.2x3.2 | 5.6x6.2x3.2 | 5.6x6.2x3.2 |

KM Model NO. PBSS-905, 1005 O

It is designed for small containers Mouth-to-Mouth design. Mouth-to-Mouth design can improve two-time production for double-station machines. It creates a unique and new mold design and auto cutting device. It can increase machine stability and decrease defective rates. This is the latest high-producion machine technology.

Powerful 4 tie-bars type mold clamping system combined with 8 die-head design. It can produce any kind of small and medium container at high speeds. Available to equip with auto deflashing device and take-out robot to achieve fully automatic and highly efficient production. Or it can equip with specialized take-out robot and conveyor to take out products from single side in order to have convenient production-line formulation.

| MODEL NO. | UNIT | PBSS-905O | PBSS-1005O |

| Prodcut max. capacity --Mouth-to-Mouth Bottle --Non Mouth-to-Mouth Bottle |

C.C. | 60-130 120-300 |

120-180 160-400 |

| Mould center distance | mm | 80*7 | 80*7 |

| Outer diameter of die mouth | mm | 35 | 35 |

| Min./Max. dia. Of product | mm | 35-55 | 35-55 |

| Screw Diameter | mm | 95 | 100 |

| Screw L/D Ratio | L/D | 24/1 | 24/1 |

| Inverter Motor | HP | 75 | 75 |

| Screw Speed | r.p.m | 15-65 | 15-65 |

| Extruding Capacity | Kg/hr | 150 | 180 |

| Clamping Force | Ton | 11 | 12 |

| Hydraulic Drive Motor | HP | 40 | 40 |

| Dry cycle | Sec. | 6.5*2 | 6.5*2 |

| Air Pressure | Kg/cm² | 8-10 | 8-10 |

| Air Consumption | L/min | 3000 | 3500 |

| Total Eletric Power | KW | 128 | 131 |

| Machine N.W. | Kg | 20000 | 22000 |